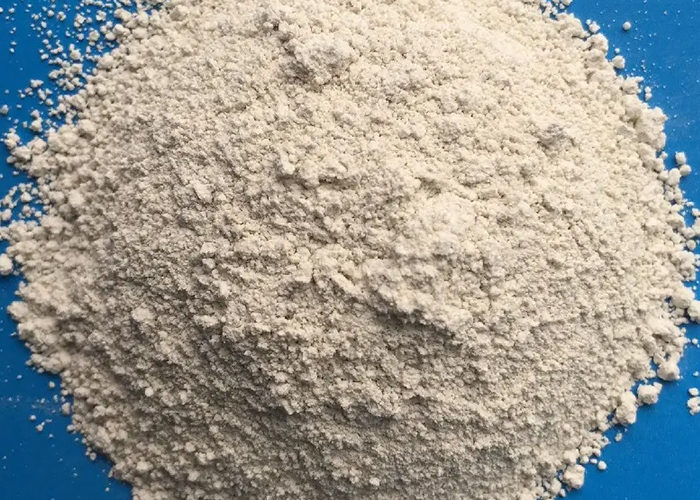

PCC

Precipitated Calcium Carbonate

An Introduction to Precipitated Calcium Carbonate (PCC)

Precipitated Calcium Carbonate (PCC) is an exquisitely refined, synthetic variant of calcium carbonate, crafted through a meticulously controlled reaction between calcium hydroxide and carbon dioxide. This process affords unparalleled precision in regulating particle size and morphology, yielding a product distinguished by its exceptional purity and uniformity.

At Yamuna Calcium, our PCC emerges from an exacting synthesis, producing ultra fine calcium carbonate particles of remarkable clarity and consistency. This makes it an exemplary choice for industries demanding superior brightness and opacity, such as paper manufacturing, plastics production, and paint formulation.

Key Properties & Advantages of PCC

Exceptional Brightness: Imparts striking whiteness and enhanced opacity to finished products, rendering it indispensable for the paper and paint sectors.

Precisely Engineered Particle Size: Facilitates a flawless surface finish and lustrous gloss, elevating the quality of applications in plastics and coatings.

Uncompromising Purity: Devoid of contaminants, it guarantees optimal efficacy in delicate applications, including pharmaceuticals and food-grade formulations.

| Particulars | Observation | Analysis Method |

|---|---|---|

| Calcium Carbonate as CaCO3 | 98% | IS 918 -1985 (A-5) |

| Whiteness | 99% | Laser Spectra |

| Crystal Structure | Calcitic | Megan Test |

| ph | 9.5 | Digital pH Meter / IS 918-1985 (A-12) |

| Bulk Density | 0.45 | IS 918 -1985(A-4) |

| Loss on Drying at 105°C | 0.40% | IS 918 -1985(A-3) |

| Moisture | 0.5% | 0.6%IS 918 -1985 |

| Silica as SiO2 | 0.05% | Gravimetric method |

| Iron as Fe | 0.00% | IS918 -1985 (A-8) |

| Mgo | 0.50% | IS 918 -1985 |

| Solution in 5N HCL | Clear | N-A |

| Linseed Oil Absorption | 35gm/100gm | IS 918 -1985 |

| ph after sterilization. (095% solution in potable water) | 9.8 | In-House |

| Matter insoluble in HCL | 0.40% | IS 918 -1985(A-7) |

| Particle Size | D50 - 4µ m ± 0.5 µ m | Malvern Particle Analyzer 3000 E |

Wire & Cable Industry

| Particulars | Observation | Analysis Method |

|---|---|---|

| Calcium Carbonate as CaCO3 | 98% | IS 918-1985(A-5) |

| Whiteness | 99% | Laser Spectra |

| Crystal Structure | Calcitic | Megan Test |

| ph | 9.40 - 9.50 | Digital pH Meter /IS 918-1985(A-12) |

| Residue on 325 mesh | 0.15% | IS 918-1985(A-2) |

| Bulk Density | 0.86-0.88gm/ml | IS 918-1985(A-4) |

| Loss on Drying at 105°C | 0.64% | IS 918-1985(A-3) |

| Silica as SiO2 | 0.05% | Gravimetric method |

| Iron as Fe | 0.00% | IS 918-1985 (A-8) |

| Solution in 5N HCL | Clear | N-A |

| Matter insoluble in HCL | 0.40% | IS 918-1985(A-7) |

| Particle Size | D50 - 5 µ m ± 0.5 µ m / D97 - 18 µ m ± 0.5 µ m | Malvern Particle Analyzer 3000 E |

Dentifrice Grade

| Particulars | Observation | Analysis Method |

|---|---|---|

| Calcium Carbonate as CaCO3 | 98% | IS 918 -1985 (A-5) |

| Whiteness | 98.9% | Laser Spectra |

| Crystal Structure | Calcitic | Megan Test |

| ph | 9.62-9.63 | Digital pH Meter / IS 918-1985 (A-12) |

| Bulk Density | 0.80-0.90gm/ml | IS 918 -1985(A-4) |

| Oil Absorption | 38 ml/100gm | Absorptometer |

| Loss on Drying at 105°C | 0.44% | IS 918 -1985(A-3) |

| Silica as SiO2 | 0.05% | Gravimetric method |

| Iron as Fe | 0.00% | IS918 -1985 (A-8) |

| Solution in 5N HCL | Clear | N-A |

| ph after sterilization. (095% solution in potable water) | 9.8 | In-House |

| Matter insoluble in HCL | 0.40% | IS 918 -1985(A-7) |

| Particle Size | D50 - 5 µ m ± 0.5 µ m / D97 - 15 µ m ± 0.5 µ m | Malvern Particle Analyzer |

Pipes & PVC Industry

| Particulars | Observation | Analysis Method |

|---|---|---|

| Calcium Carbonate as CaCO3 | 97% | IS 918-1985(A-5) |

| Whiteness | 98.9% | Laser Spectra |

| Crystal Structure | Calcitic | Megan Test |

| ph | 9.40 - 9.50 | Digital pH Meter /IS 918-1985(A-12) |

| Residue on 325 mesh | 0.15% | IS 918-1985(A-2) |

| Bulk Density | 0.65gm/ml | IS 918-1985(A-4) |

| Loss on Drying at 105°C | 0.64% | IS 918-1985(A-3) |

| Silica as SiO2 | 0.05% | Gravimetric method |

| Iron as Fe | 0.00% | IS 918-1985 (A-8) |

| Solution in 5N HCL | Clear | N-A |

| Matter insoluble in HCL | 0.40% | IS 918-1985(A-7) |

| Particle Size | D50 - 5 µ m ± 0.5 µ m / D90 - 13 µ m ± 0.5 µ m | Malvern Particle Analyzer 3000 E |

Paper & Printing Industries

| Particulars | Specification | Observation | Analysis Method |

|---|---|---|---|

| Calcium Carbonate as CaCO3 | 98%-99% | 98% | IS 918 -1985 (A-5) |

| Whiteness | 98%Min | 99% | Laser Spectra |

| Crystal Structure | Calcitic-(Scalenohedral) | Calcitic-(Scalenohedral) | Megan Test |

| ph | 9.0 to 10.0 | 9.5 | Digital pH Meter / IS 918-1985 (A-12) |

| Bulk Density | 0.5-0.55gm/ml | 0.45gm/ml | IS 918 -1985(A-4) |

| Loss on Drying at 105°C | 0.8%Max. | 0.40% | IS 918 -1985(A-3) |

| Moisture | 0.8% | 0.5% | IS 918 -1985 |

| Silica as SiO2 | 0.07%Max | 0.05% | Gravimetric method |

| Iron as Fe | 0.01%Max | 0.00% | IS918 -1985 (A-8) |

| Mgo | 0.5%Max | 0.50% | IS 918 -1985 |

| Solution in 5N HCL | Clear | Clear | N-A |

| Linseed Oil Absorption | 35gm/100gm | 35gm/100gm | IS 918 -1985 |

| ph after sterilization. (095% solution in potable water) | 9.0 to 10.0 | 9.8 | In-House |

| Matter insoluble in HCL | 0.5%Max | 0.40% | IS 918 -1985(A-7) |

| Particle Size | D50 - 4µ m ± 0.5 µ m | Malvern Particle Analyzer 3000 E |

Tires Industries

| Particulars | Observation | Analysis Method |

|---|---|---|

| Calcium Carbonate as CaCO3 | 98% | IS 918 -1985 (A-5) |

| Whiteness | 99% | Laser Spectra |

| Crystal Structure | Calcitic / Aragonite | Megan Test |

| ph | 9.5 | Digital pH Meter / IS 918-1985 (A-12) |

| Bulk Density | 0.45gm/ml | IS 918 -1985(A-4) |

| Loss on Drying at 105°C | 0.40% | IS 918 -1985(A-3) |

| Moisture | 0.5% | 0.6%IS 918 -1985 |

| Silica as SiO2 | 0.05% | Gravimetric method |

| Iron as Fe | 0.00% | IS918 -1985 (A-8) |

| Mgo | 0.50% | IS 918 -1985 |

| Solution in 5N HCL | Clear | N-A |

| Linseed Oil Absorption | 35gm/100gm | IS 918 -1985 |

| ph after sterilization. (095% solution in potable water) | 9.8 | In-House |

| Matter insoluble in HCL | 0.40% | IS 918 -1985(A-7) |

| Particle Size | D50 - 4µ m ± 0.5 µ m | Malvern Particle Analyzer 3000 E |

Footwear Industries

| Particulars | Observation | Analysis Method |

|---|---|---|

| Calcium Carbonate as CaCO3 | 98% | IS 918 -1985 (A-5) |

| Whiteness | 99% | Laser Spectra |

| Crystal Structure | Calcitic / Aragonite | Megan Test |

| ph | 9.5 | Digital pH Meter / IS 918-1985 (A-12) |

| Bulk Density | 0.45gm/ml | IS 918 -1985(A-4) |

| Loss on Drying at 105°C | 0.40% | IS 918 -1985(A-3) |

| Moisture | 0.5% | 0.6%IS 918 -1985 |

| Silica as SiO2 | 0.05% | Gravimetric method |

| Iron as Fe | 0.00% | IS918 -1985 (A-8) |

| Mgo | 0.50% | IS 918 -1985 |

| Solution in 5N HCL | Clear | N-A |

| Linseed Oil Absorption | 35gm/100gm | IS 918 -1985 |

| ph after sterilization. (095% solution in potable water) | 9.8 | In-House |

| Matter insoluble in HCL | 0.40% | IS 918 -1985(A-7) |

| Particle Size | D50 - 4µ m ± 0.5 µ m | Malvern Particle Analyzer 3000 E |

Food Industries

| Particulars | Specification | Observation | Analysis Method |

|---|---|---|---|

| Calcium Carbonate as CaCO3 | 98%-99% | 98% | IS 918 -1985 (A-5) |

| Whiteness | 98%Min | 99% | Laser Spectra |

| Crystal Structure | Calcitic-(Scalenohedral) | Calcitic | Megan Test |

| ph | 9.0 to 10.0 | 9.5 | Digital pH Meter / IS 918-1985 (A-12) |

| Bulk Density | 0.5-0.55gm/ml | 0.45gm/ml | IS 918 -1985(A-4) |

| Loss on Drying at 105°C | 0.8%Max. | 0.40% | IS 918 -1985(A-3) |

| Moisture | 0.8% | 0.5% | IS 918 -1985 |

| Silica as SiO2 | 0.07%Max | 0.05% | Gravimetric method |

| Iron as Fe | 0.01%Max | 0.00% | IS918 -1985 (A-8) |

| Mgo | 0.5%Max | 0.50% | IS 918 -1985 |

| Solution in 5N HCL | Clear | Clear | N-A |

| Linseed Oil Absorption | 35gm/100gm | 35gm/100gm | IS 918 -1985 |

| ph after sterilization. (095% solution in potable water) | 9.0 to 10.0 | 9.8 | In-House |

| Matter insoluble in HCL | 0.5%Max | 0.40% | IS 918 -1985(A-7) |

| Particle Size | D50 - 4µ m ± 0.5 µ m | Malvern Particle Analyzer 3000 E |

Soap & Detergents Industiries

| Particulars | Specification | Observation | Analysis Method |

|---|---|---|---|

| Calcium Carbonate as CaCO3 | 98%-99% | 98% | IS 918 -1985 (A-5) |

| Whiteness | 98%Min | 99% | Laser Spectra |

| Crystal Structure | Calcitic-(Scalenohedral) | Calcitic | Megan Test |

| ph | 9.0 to 10.0 | 9.5 | Digital pH Meter / IS 918-1985 (A-12) |

| Bulk Density | 0.5-0.55gm/ml | 0.45gm/ml | IS 918 -1985(A-4) |

| Loss on Drying at 105°C | 0.8%Max. | 0.40% | IS 918 -1985(A-3) |

| Moisture | 0.8% | 0.5% | IS 918 -1985 |

| Silica as SiO2 | 0.07%Max | 0.05% | Gravimetric method |

| Iron as Fe | 0.01%Max | 0.00% | IS918 -1985 (A-8) |

| Mgo | 0.5%Max | 0.50% | IS 918 -1985 |

| Solution in 5N HCL | Clear | Clear | N-A |

| Linseed Oil Absorption | 35gm/100gm | 35gm/100gm | IS 918 -1985 |

| ph after sterilization. (095% solution in potable water) | 9.0 to 10.0 | 9.8 | In-House |

| Matter insoluble in HCL | 0.5%Max | 0.40% | IS 918 -1985(A-7) |

| Particle Size | D50 - 4µ m ± 0.5 µ m | Malvern Particle Analyzer 3000 E |

Rubber Industries

| Particulars | Specification | Observation | Analysis Method |

|---|---|---|---|

| Calcium Carbonate as CaCO3 | 98%-99% | 98% | IS 918 -1985 (A-5) |

| Whiteness | 98%Min | 99% | Laser Spectra |

| Crystal Structure | Calcitic-(Scalenohedral) | Aragonite | Megan Test |

| ph | 9.0 to 10.0 | 9.5 | Digital pH Meter / IS 918-1985 (A-12) |

| Bulk Density | 0.5-0.55gm/ml | 0.45gm/ml | IS 918 -1985(A-4) |

| Loss on Drying at 105°C | 0.8%Max. | 0.40% | IS 918 -1985(A-3) |

| Moisture | 0.8% | 0.5% | IS 918 -1985 |

| Silica as SiO2 | 0.07%Max | 0.05% | Gravimetric method |

| Iron as Fe | 0.01%Max | 0.00% | IS918 -1985 (A-8) |

| Mgo | 0.5%Max | 0.50% | IS 918 -1985 |

| Solution in 5N HCL | Clear | Clear | N-A |

| Linseed Oil Absorption | 35gm/100gm | 35gm/100gm | IS 918 -1985 |

| ph after sterilization. (095% solution in potable water) | 9.0 to 10.0 | 9.8 | In-House |

| Matter insoluble in HCL | 0.5%Max | 0.40% | IS 918 -1985(A-7) |

| Particle Size | D50 - 4µ m ± 0.5 µ m | Malvern Particle Analyzer 3000 E |

Food and Pharmaceuticals Industry

| Particulars | Observation | Analysis Method |

|---|---|---|

| Calcium Carbonate as CaCO3 | 98% | IS 918 -1985 (A-5) |

| Whiteness | 99% | Laser Spectra |

| Crystal Structure | Calcitic / Aragonite | Megan Test |

| ph | 9.5 | Digital pH Meter / IS 918-1985 (A-12) |

| Bulk Density | 0.45gm/ml | IS 918 -1985(A-4) |

| Loss on Drying at 105°C | 0.40% | IS 918 -1985(A-3) |

| Moisture | 0.5% | 0.6%IS 918 -1985 |

| Silica as SiO2 | 0.05% | Gravimetric method |

| Iron as Fe | 0.00% | IS918 -1985 (A-8) |

| Mgo | 0.50% | IS 918 -1985 |

| Solution in 5N HCL | Clear | N-A |

| Linseed Oil Absorption | 35gm/100gm | IS 918 -1985 |

| ph after sterilization. (095% solution in potable water) | 9.8 | In-House |

| Matter insoluble in HCL | 0.40% | IS 918 -1985(A-7) |

| Particle Size | D50 - 4µ m ± 0.5 µ m | Malvern Particle Analyzer 3000 E |

Building & Construction

| Particulars | Specification | Observation | Analysis Method |

|---|---|---|---|

| Calcium Carbonate as CaCO3 | 98%-99% | 98% | IS 918 -1985 (A-5) |

| Whiteness | 98%Min | 99% | Laser Spectra |

| Crystal Structure | Calcitic-(Scalenohedral) | Calcitic | Megan Test |

| ph | 9.0 to 10.0 | 9.5 | Digital pH Meter / IS 918-1985 (A-12) |

| Bulk Density | 0.5-0.55gm/ml | 0.9gm/ml | IS 918 -1985(A-4) |

| Loss on Drying at 105°C | 0.8%Max. | 0.40% | IS 918 -1985(A-3) |

| Moisture | 0.8% | 0.5% | IS 918 -1985 |

| Silica as SiO2 | 0.07%Max | 0.05% | Gravimetric method |

| Iron as Fe | 0.01%Max | 0.00% | IS918 -1985 (A-8) |

| Mgo | 0.5%Max | 0.50% | IS 918 -1985 |

| Solution in 5N HCL | Clear | Clear | N-A |

| Linseed Oil Absorption | 35gm/100gm | 35gm/100gm | IS 918 -1985 |

| ph after sterilization. (095% solution in potable water) | 9.0 to 10.0 | 9.8 | In-House |

| Matter insoluble in HCL | 0.5%Max | 0.40% | IS 918 -1985(A-7) |

| Particle Size | D50 - 6µ m ± 0.5 µ m | Malvern Particle Analyzer 3000 E |

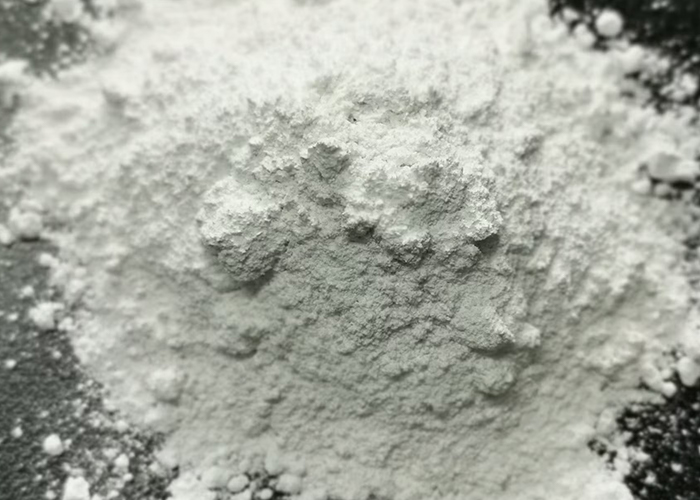

GCC

Ground Calcium Carbonate

Overview of Ground Calcium Carbonate (GCC)

Ground Calcium Carbonate (GCC) is a refined material obtained from the mechanical pulverization of naturally abundant limestone. Its inherent attributes render it an economical and multifaceted additive, widely embraced across diverse industries.

Extracted from pristine limestone deposits, our GCC undergoes meticulous processing to yield a spectrum of particle sizes, ensuring adaptability for use in applications ranging from rubber and adhesives to sealants and construction materials.

Distinguished Characteristics & Benefits of GCC

Economical Filler: Substantially lowers production expenses in plastics, rubber, and adhesive formulations while preserving exceptional quality standards.

Enhanced Mechanical Attributes: Bolsters rigidity and fortifies impact resilience, significantly improving the performance of polymer-based products.

Ecological Advantages: Serves as a natural buffering agent, mitigating environmental harm in processes such as flue gas desulfurization.

| CHEMICAL COMPOSITIONS | CHEMICAL COMPOSITIONS | PHYSICAL PROFERTIES | PHYSICAL PROFERTIES | METHOD |

|---|---|---|---|---|

| Calcium Carbonate as CaCO3 | ≥ 98 % | Whiteness | ≥ 98 % | Konica Minolta CR 410 |

| Magnesium Oxide MgO | ≤ 0.67 % | Brightness | ≥ 94 % | Konica Minolta CR 410 |

| Iron Qxide Fe2O3 | < 0.01 % | Moisture | ≤ 0.25 % | |

| Bulk Density | 1.3gm/ml ± 1 | Specific Gravity | 2.7g/cm3 | |

| Aluminium Oxide Al2O3 | < 0.1 % | Oil Absorption | 20ml/100g CaCO3 | |

| Silica Oxide SiO2 | < 0.1 % | Loss on Ignition | ≤ 43.8 % | |

| Natri Oxide Na2O | < 0.16 % | Hardness | 3 Moh | |

| Coated percentage | None |

WGCC

Wet Ground Calcium Carbonate

An Overview of Wet Ground Calcium Carbonate (WGCC)

Wet Ground Calcium Carbonate (WGCC) represents a meticulously refined variant of calcium carbonate, extensively employed as a versatile functional filler across a multitude of industries. Sourced from exceptionally pure natural limestone, WGCC undergoes a sophisticated wet grinding process to attain an ultra-fine particle size and exceptional attributes that distinguish it from conventional alternatives.

Distinctive Characteristics and Benefits of WGCC

Exceptionally Fine Particle Size with uniform distribution: The intricate production process yields particles of remarkably diminutive and consistent dimensions, significantly elevating the material’s efficacy and performance in diverse applications.

Superior Brightness and Whiteness: Renowned for its outstanding luminosity and pristine whiteness, WGCC is a preferred choice in applications where aesthetic excellence and visual appeal are paramount.

Enhanced Dispersion and Surface Refinement: WGCC exhibits exemplary dispersion characteristics, rendering it indispensable in the formulation of paints, coatings, and polymer-based products, where it contributes to a flawlessly smooth surface finish.

Optimized Light Scattering and Opacity: Its ability to enhance light reflection and opacity makes WGCC an invaluable asset in the production of paper, paints, and coatings, delivering vivid, high-quality finishes with remarkable vibrancy.

Minimized Oil Absorption: With its reduced oil absorption capacity, WGCC promotes superior flow properties, making it an ideal component in the manufacturing of paints, adhesives, and plastics, where fluidity and ease of application are critical.

Through its remarkable properties, WGCC stands as a cornerstone material, seamlessly integrating functionality with aesthetic enhancement across a broad spectrum of industrial applications.

| Particulars | Observation | Analysis Method |

|---|---|---|

| Calcium Carbonate as CaCO3 | 97% | IS 918-1985(A-5) |

| Brightness | 92% - 93% | Laser Spectra |

| Crystal Structure | Calcitic | Megan Test |

| ph | 9.0 to 9.25 | Digital pH Meter /IS 918-1985(A-12) |

| Silica as SiO2 | 0.05% | Gravimetric method |

| Solution in 5N HCL | Clear | N-A |

| Matter insoluble in HCL | 0.40% | IS 918-1985(A-7) |

| Mean size : D60 | 1.8 µm | Malvern Mastersizer 3000 E |

CaO

Calcium Oxide (CaO)

Overview of Calcium Oxide (Quicklime) – CaO

Calcium Oxide (CaO), widely referred to as quicklime, is a highly reactive and adaptable inorganic compound. Its versatility makes it invaluable across industrial, chemical, and environmental sectors, owing to its exceptional reactivity, purity, and wide-ranging utility. Quicklime is produced through the thermal breakdown of limestone (calcium carbonate, CaCO₃) at elevated temperatures, yielding a potent and indispensable material.

Key Characteristics & Benefits of Calcium Oxide (CaO)

Elevated Reactivity: Swiftly interacts with water and acids, rendering it highly suitable for chemical processes.

Pronounced Alkalinity: Employed in water treatment and environmental contexts to adjust pH levels effectively.

Thermal Endurance & Stability: Maintains integrity under intense heat, making it ideal for use in steel production, cement manufacturing, and refractory applications.

Enhanced Surface Area & Porosity: Promotes efficient absorption and rapid reactions, offering a cost-efficient solution for industrial needs.

| Particulars | Specification | Observation | Analysis Method |

|---|---|---|---|

| Calcium Carbonate as CaCO3 | 98%-99% | 98% | IS 918 -1985 (A-5) |

| ph | 9.0 to 10.0 | 9.5 | Digital pH Meter / IS 918-1985 (A-12) |

| Bulk Density | 0.5-0.55gm/ml | 0.9gm/ml | IS 918 -1985(A-4) |

| Loss on Drying at 105°C | 0.8%Max. | 0.40% | IS 918 -1985(A-3) |

| Moisture | 0.8% | 0.5% | IS 918 -1985 |

| Silica as SiO2 | 0.07%Max | 0.05% | Gravimetric method |

| Iron as Fe | 0.01%Max | 0.00% | IS918 -1985 (A-8) |

| Mgo | 0.5%Max | 0.50% | IS 918 -1985 |

DP

Dolomite Powder (Low Iron) / Calcite for the Glass Industry

Dolomite Powder (Low Iron) / Calcite for the Glass Industry

Overview

In glass manufacturing, precision and purity are everything. Even trace amounts of iron or silica can compromise clarity, brightness, and color. Yamuna Calcium’s Low Iron Dolomite Powder / Calcite is engineered specifically for the glass industry, ensuring exceptional transparency, strength, and consistency. With a tightly controlled chemical profile and zero moisture, it helps manufacturers achieve superior quality glass products with unmatched brilliance.

Why Choose Our Dolomite / Calcite?

Low Iron, Crystal-Clear Glass – With Fe₂O₃ levels maintained between 150–300 PPM, our dolomite prevents unwanted greenish tones, enabling flawless clarity.

Balanced Chemistry – Typical CaO content of 38% and MgO at 17% deliver the ideal fusion for smooth melting and enhanced durability of finished glass.

Ultra-Low Impurities – Minimal SiO₂ (1.0%) and Al₂O₃ (0.3%) guarantee consistent furnace performance and reduce processing defects.

Moisture-Free Assurance – Completely dry material eliminates clumping and storage issues, ensuring smooth handling.

Optimised Grain Size – Controlled particle distribution promotes uniform melting, higher furnace efficiency, and fewer production defects.

Applications in Glass Industry

● Float Glass – Maintains maximum clarity with reduced tint.

● Container Glass – Enhances strength, durability, and resistance to chemicals.

● Specialty & Optical Glass – Delivers improved transparency and superior refractive properties.

● Glazes & Frits – Provides uniform melting, glossy finish, and smooth surface quality.

At Yamuna Calcium, our dolomite powder is more than just a raw material—it is a performance enhancer that ensures glass with higher purity, durability, and aesthetic appeal.

Typical Specifications

Chemical Composition

● SiO₂: 1.0% Typical

● Fe₂O₃: 150–300 PPM

● Al₂O₃: 0.3% Typical

● CaO: 38% Typical

● MgO: 17% Typical

● Moisture: NIL

Grain Size Distribution

● 2057 micron: NIL

● 1405 micron: 10% max (preferable 5%)

● <150 micron: 10% max (preferable 5%)

Packaging & Support

Available in bulk bags, 25/50 kg HDPE bags, or customised packaging, our dolomite is delivered with reliability and consistency. Each batch undergoes rigorous testing for chemical purity and particle size, accompanied by a Certificate of Analysis (CoA) for complete quality assurance.